¶ IronOX AMR

¶ Contents

- Robot Anatomy: Components and Connections

- Network Configuration and Remote Access

- Starting the AMR

- Teleoperation Setup

- Safety PLC Connection and E-Stop Logic Modification

- Connecting to the ELMO Motor Driver

- Software Architecture Overview

- Autonomous Navigation Setup

- RVIZ Visualization Setup

- Debugging: Important Topics and Commands

- Sound Configuration

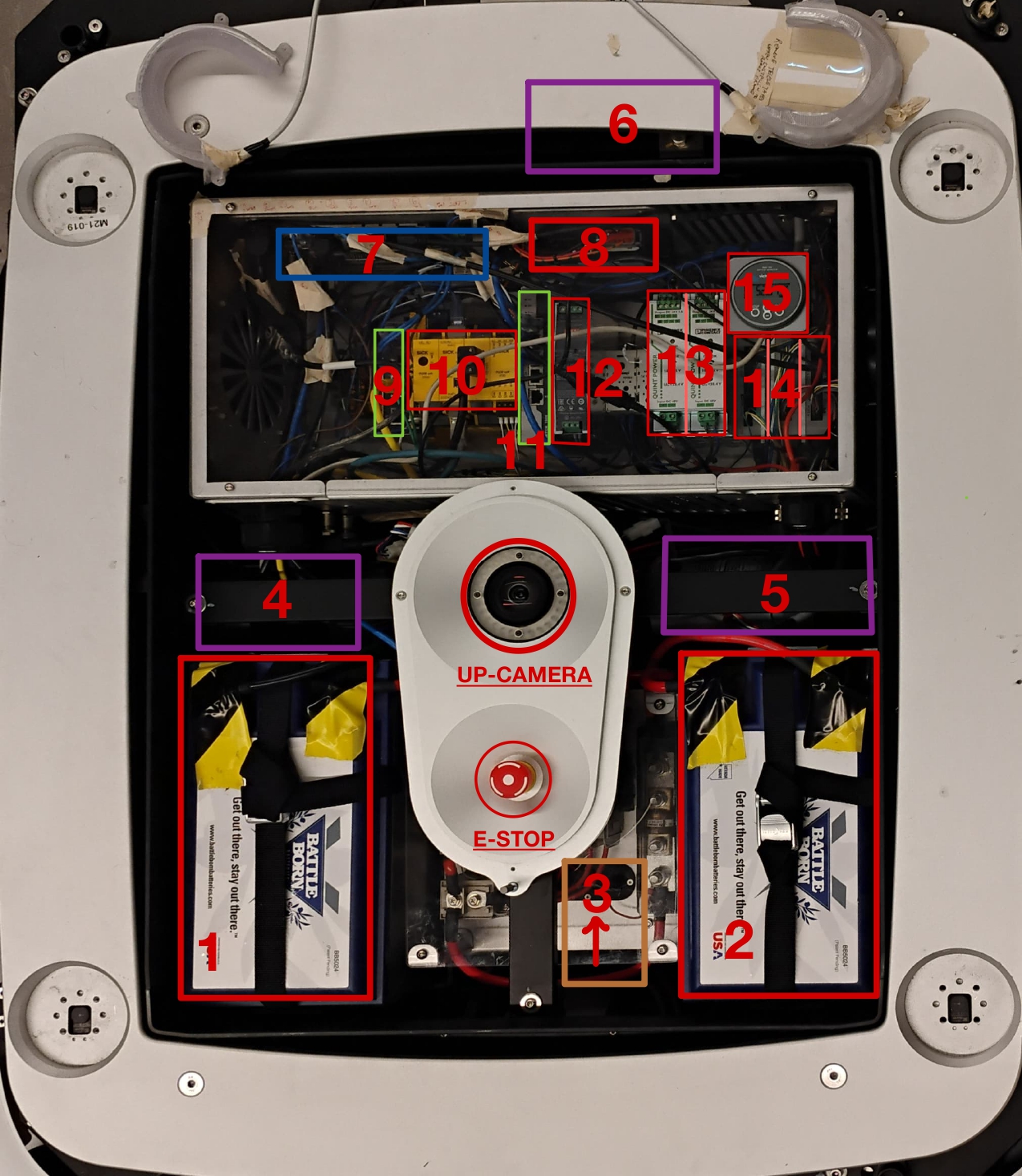

¶ 1. Robot Anatomy: Components and Connections

¶ 1.1 Components Inside the Robot:

| Number | Component Name | Description |

|---|---|---|

| 1, 2 | 24V LiFe Battery | Both batteries are connected in series for 48V power source Link |

| 3 | Connection Plate | Act as a ground(-ve) for power distribution. All the MCBs and Fuse are here |

| 4,5 | BLDC Wheel Motors | Wheel motors, attached to robot diff drive wheels. |

| 6 | BLDC Lifter Motor | Motor for the lifter |

| 7 | Onboard PC | 7th Gen Core™ i7 processor running Ubuntu 20.04 Link |

| 8 | Radio | Radio receiver for emergency stop |

| 9 | LAN Switch | Switch to connect PLC Onboard PC |

| 10 | Safety PLC | It's SICK FX3-CPU for safety system Link |

| 11 | LAN Switch | Switch to connect PLC and Lidars |

| 12 | DC-DC 48V-48V converter | MeanWell's DDR 120C-48 dc to dc converter. Maybe used as isolator. Link |

| 13 | Two DC-DC 48V-24V converter | Phoenix Contact 48V to 24V, 5 amp DC-DC converter Link |

| 14 | Three Motor Controllers | Elmo Motor controllers for each motors (left, right wheel and lifter) Link |

| 15 | Battery Indicator | Connected to Battrey BMS. (Ideally it should be outside) |

| 16 | SICK LiDAR | Connected to Safety PLC via ethernet and sharing the network with the Onboard PC. Range 10m Link |

¶ 1.2 Power Box Interface:

| Number | Component Name | Description |

|---|---|---|

| 1 | Reset Button | Push button to release Motor Contractor |

| 2 | Power ON/OFF Switch | Toggle to turn on the robot |

| 3 | Charging Port | Plug charger male end here |

| 4 | LAN Port | Connects with the robot's internal network |

| 5 | USB port | Connects to the onboard PC |

| 6 | Hdmi port | Connects to the onboard PC |

¶ 1.3 Sensor Configuration:

- LiDARs: 3 units (Front, Rear Left, Rear Right)

- Cameras: 1 upward-facing unit, additional front-facing units (not visible in images)

- LED Indicators: Front and rear LED strips for status indication

- Emergency Controls: Centrally located E-STOP button

- Power System: Battery and charging connections.

- Motors: Linked via the ELMO motor driver.

- Sensors: Includes LIDAR, cameras, and IMUs with labeled ports.

- Main Controller: Connections for the onboard computer.

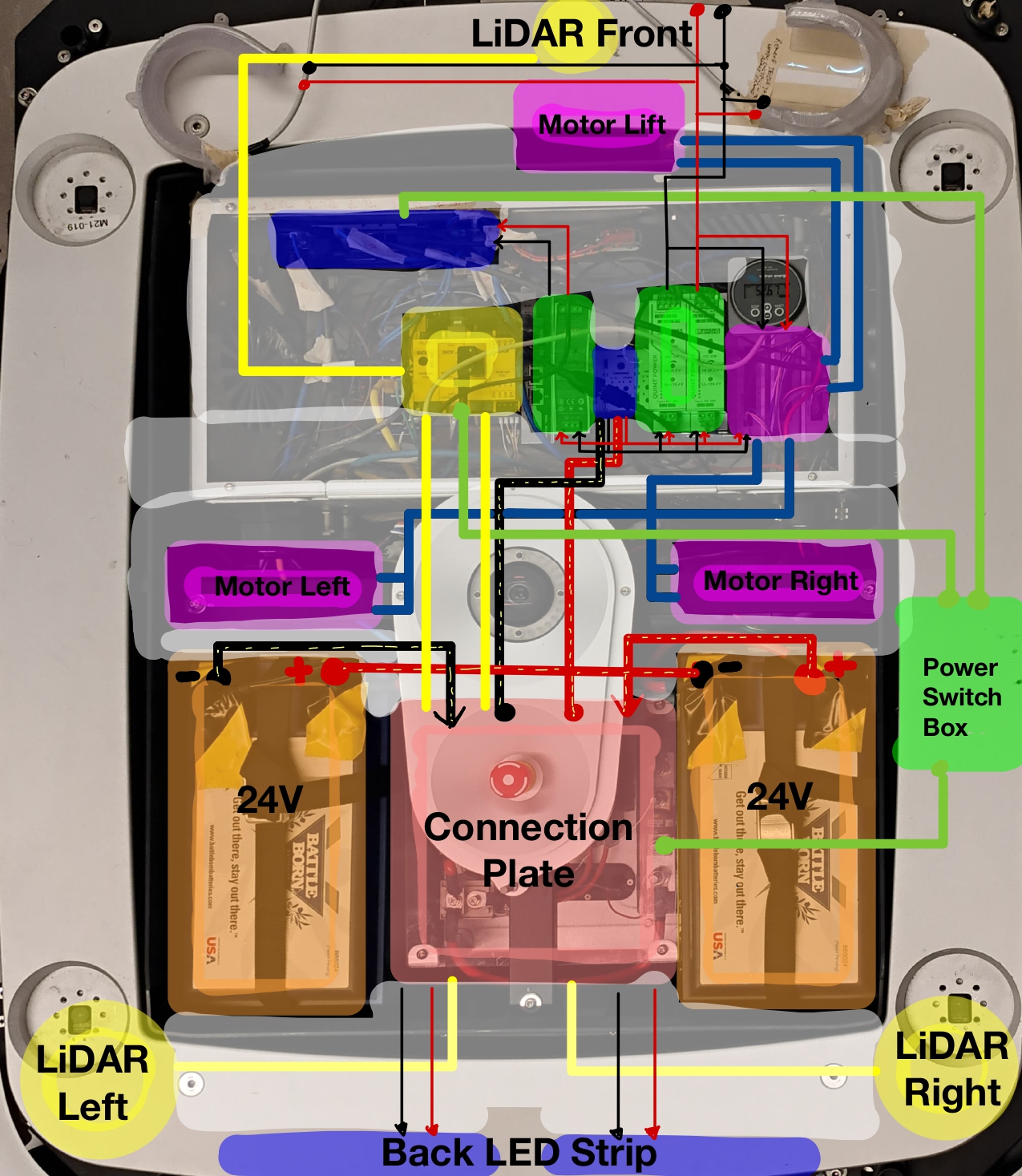

¶ 1.4 Connection Overview:

¶ Figure 1.4: Major component's connection Overview

¶ 2. Network Configuration and Remote Access

¶ Network Information

The IronOX AMR uses a dedicated network configuration for its components. Below are the login credentials and IP addresses for all system components:

¶ Login Credentials

- Username:

iron - Password:

iron

¶ Component IP Addresses

| Component | IP Address |

|---|---|

| Onboard PC | 10.20.20.42 |

| Safety PLC | 10.20.20.204 |

| Rear Left Lidar | 10.20.20.203 |

| Rear Right Lidar | 10.20.20.202 |

| Front Lidar | 10.20.20.201 |

¶ SSH Setup

Follow these steps to establish a secure connection to the IronOX AMR:

-

Network Configuration:

- Connect your laptop to the same network as the robot

- Configure a compatible static IP (recommended:

10.20.20.100) - Set subnet mask to

255.255.255.0

-

Simple Connection Setup:

- Connect with robot vis SSH:

ssh iron@10.20.20.42 -XC -

Quick Connection Setup (Optional):

- Install sshpass utility if not already present:

$ sudo apt-get install sshpass - Add this convenient alias to your

~/.bashrcfile:$ echo 'alias ironox="sshpass -p iron ssh iron@10.20.20.42"' >> ~/.bashrc $ source ~/.bashrc - Connect with a single command:

$ ironox

- Install sshpass utility if not already present:

-

Connection Troubleshooting:

- If unable to connect, verify:

- Robot power status is ON

- Your network configuration matches requirements

- Network connectivity with ping:

$ ping 10.20.20.42

- If unable to connect, verify:

¶ RVIZ Visualization

The robot's software stack runs in Docker containers on the onboard PC. To visualize ROS topics on your host system using RVIZ, you need to configure a ROS multi-machine setup that allows your local system to connect to the robot's ROS master.

¶ Prerequisites

- Host system connected to the robot's network (IP:

10.20.20.100) - Docker installed on your host system

- Basic understanding of ROS networking concepts

¶ Step 1: Docker Environment Setup

- For First time setup

Set up a ROS Noetic environment using Docker to ensure compatibility:

# Pull the ROS Noetic Docker image

docker pull althack/ros:noetic-gazebo-2025-05-01

# Allow Docker container to access X11 display

xhost +local:docker

# Create and run the container with network access

docker run -it --net=host --privileged --name iron_rviz \

-e DISPLAY=$DISPLAY -v /tmp/.X11-unix:/tmp/.X11-unix:rw \

althack/ros:noetic-gazebo-2025-05-01 bash

- If you ahve already environment setup:

- Start the container (only one time)

docker start iron_rviz

xhost +

- Open the container

docker exec -it iron_rviz bash

¶ Step 2: ROS Multi-Machine Configuration

Configure your host system to communicate with the robot's ROS master:

-

Environment Variables Setup:

Inside the Docker container, configure ROS networking:echo "source /opt/ros/noetic/setup.bash" >> ~/.bashrc echo "export ROS_MASTER_URI=http://10.20.20.42:11311" >> ~/.bashrc echo "export ROS_IP=10.20.20.100" >> ~/.bashrc source ~/.bashrc -

Host Resolution Setup:

Configure hostname resolution for better connectivity:# Edit the hosts file sudo vim /etc/hosts # Add the following line: 10.20.20.42 m21-019

¶ Step 3: Connection Verification

Before launching RVIZ, verify that the ROS connection is working properly:

-

Test Topic Visibility:

# This should list all available topics from the robot rostopic list -

Verify Data Flow:

# Check if odometry data is being received rostopic hz /diff_drive_controller/odom # Display a single odometry message rostopic echo -n1 /diff_drive_controller/odom -

Test Additional Topics:

# Check other common robot topics rostopic hz /scan rostopic hz /tf

¶ Step 4: Launch RVIZ

Once the connection is verified, you can launch RVIZ for visualization:

-

Start RVIZ:

# Launch RVIZ with GUI support rviz -

Basic RVIZ Configuration:

- Set Fixed Frame to

base_link,odom, ormap(depending on your robot's frame setup) - Add visualization plugins for:

- LaserScan - Visualize lidar data from

/scan - TF - Display coordinate frame transformations

- Map - Show occupancy grid if SLAM is running

- LaserScan - Visualize lidar data from

- Set Fixed Frame to

¶ Troubleshooting Common Issues

Connection Problems:

- Ensure both systems are on the same network subnet

- Verify firewall settings are not blocking ROS communication ports

- Check that the robot's ROS master is running:

rostopic liston the robot

RVIZ Display Issues:

- Run

xhost +local:dockeron the host system before starting the container - Check if

$DISPLAYenvironment variable matches between host and container:

If they don't match, manually set the DISPLAY variable in the container:# On host system echo $DISPLAY # Inside Docker container echo $DISPLAYexport DISPLAY=:0.0 # or whatever your host DISPLAY shows - Verify that the Docker container has proper X11 forwarding enabled

- Check that the correct ROS topics are being published by the robot

- Ensure proper frame transformations are available via

/tf

Performance Issues:

- Reduce the update rate of high-frequency topics in RVIZ

- Consider using

rostopic hzto monitor actual publishing rates - Adjust RVIZ display settings to reduce computational load

¶ Additional Tips

- Save your RVIZ configuration file (

.rviz) for future use - Consider creating a launch file to automatically start RVIZ with the correct configuration

- Monitor network bandwidth usage when visualizing high-data topics like point clouds or images

¶ 3. Starting the AMR

¶ Steps to Start

-

Connections:

- Remove Teleop USB (Don't connect it)

- Connect LAN for SSH

-

Power On:

- Locate and toggle the power switch on the robot (refer to Section 1.2: Power Box Interface),you will hear an intial beep sound.

- The power switch is located on the right panel of the robot, near the charging port.

Figure 3.1: Power box after startup- Verify that the fans turn on, power switch light(see Figure 3.1) and indicator lights illuminate (see Figure 3.2).

- You should hear the fans running, which confirms initial power-up.

Figure 3.2: Indicator lights when powered on -

Wait for System Initialization:

- Allow the system to complete its boot sequence.

- The successful initialization is indicated by a beep sound.

- This typically takes approximately 40-50 seconds.

-

Release E-Stop:

- Release the E-stop button if it has been pressed.

-

Reset Safety Circuit:

- Press the reset button (Button1) to release the safety contactor (refer to Section 1.2: Power Box Interface for location).

- Listen for a distinct click sound, which confirms the contactor has been released.

- The robot is now ready for operation.

-

Initialize Robot Pose for Localization (Optional):

- Launch RViz (refer to Section 9: RVIZ Visualization Setup)

- Click on the "2D Pose Estimate" button in the top toolbar

- Click on the map at the robot's current position

- Drag in the direction the robot is facing to set orientation

- The robot should now be localized on the map

¶ Troubleshooting

- If no fan sound is heard when toggling the switch, check battery voltage(must be above 49 V) open the top panel.

- If the beep sound doesn't occur after waiting, the system may need to be restarted.

- If no click sound occurs after pressing reset, the safety circuit may require inspection.

¶ 4. Teleoperation Setup

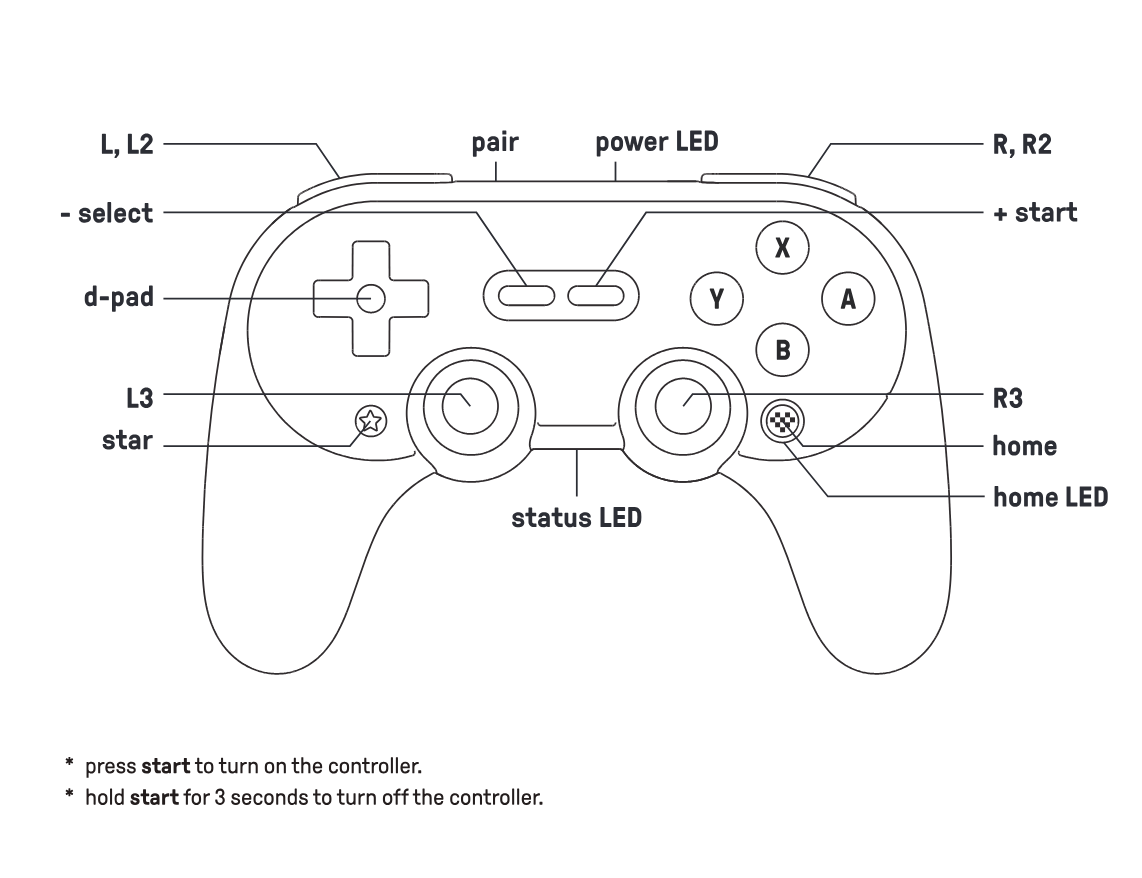

¶ Controller Overview

The IronOX AMR comes with an 8BitDo SN30_Pro+ joystick controller controller for manual operation. Any Xbox-compatible controller will also work as the system uses the JOY ROS Pkg to interpret controller data in the sensor_msgs/Joy.

¶ Controller Setup Process

| Steps | Action | Details | Reference Image |

|---|---|---|---|

| 1. | Check Connection Status | Verify the leftmost LED is illuminated green, indicating proper connection. Remove the USB and plug it back again if its not connected. |  |

| 2. | Activate Controller | If the Home LED is not blinking, press L + Star buttons simultaneously. The Home LED should begin blinking to indicate activation |

|

| 3. | Verify Controller Status | Press the L button and check the Home LED status |

|

| 4. | Operate the AMR | Control movement with the L3 joystick while holding the L button. For increased speed, use L+R buttons simultaneously |

|

¶ Control Commands

- Basic Movement: Hold

L button+ moveL3 joystick - High-Speed Mode: Hold

L+R buttons+ moveL3 joystick - Emergency Stop: Release all buttons

¶ Troubleshooting Guide

If the robot doesn't respond to controller commands after following the setup process, check these common issues:

-

Contactor Status

- Verify the contactor is engaged

- Press the

Resetbutton once more to ensure system initialization

-

Controller Communication

- If contactor is on but no response, the serial connection may be compromised

- Verification steps:

- SSH into the IronOX system (see Section 2)

- Access the test container (see Section 10)

- Monitor the

/joytopic rate while pressing controller buttons:rostopic hz /joy - If no data appears, restart the hardware container:

docker restart ros_workspace_hardware_1

-

Battery Level

- Low battery can cause intermittent controller response

- Open the top panel to check battery indicator on the BMS display panel

-

Reboot System

- If nothings works, its always better to restart the robot one more time. Make sure you have taken out the teleop USB cabel.

¶ 5. Safety PLC Connection and E-Stop Logic Modification

¶ 5.1 Required Software

The SICK FX3-CPU safety PLC requires the official SICK Safety Designer software:

- SICK Safety Designer:

- Official configuration software for SICK FX3 safety controllers

- Current version: Safety Designer Engineering Tool

- Download from SICK's official website

- Version tested on: Version 2024.02

- System Requirements:

- Windows 10, Version 22H2 (64 bit) or Windows 11, Version 23H2

- X64-based processor

- 2GHz processor or better

- 1GB available disk space

- Additional software Microsoft .Net Framework 4.7.2 is a prerequisite

¶ 5.2 Connection Process

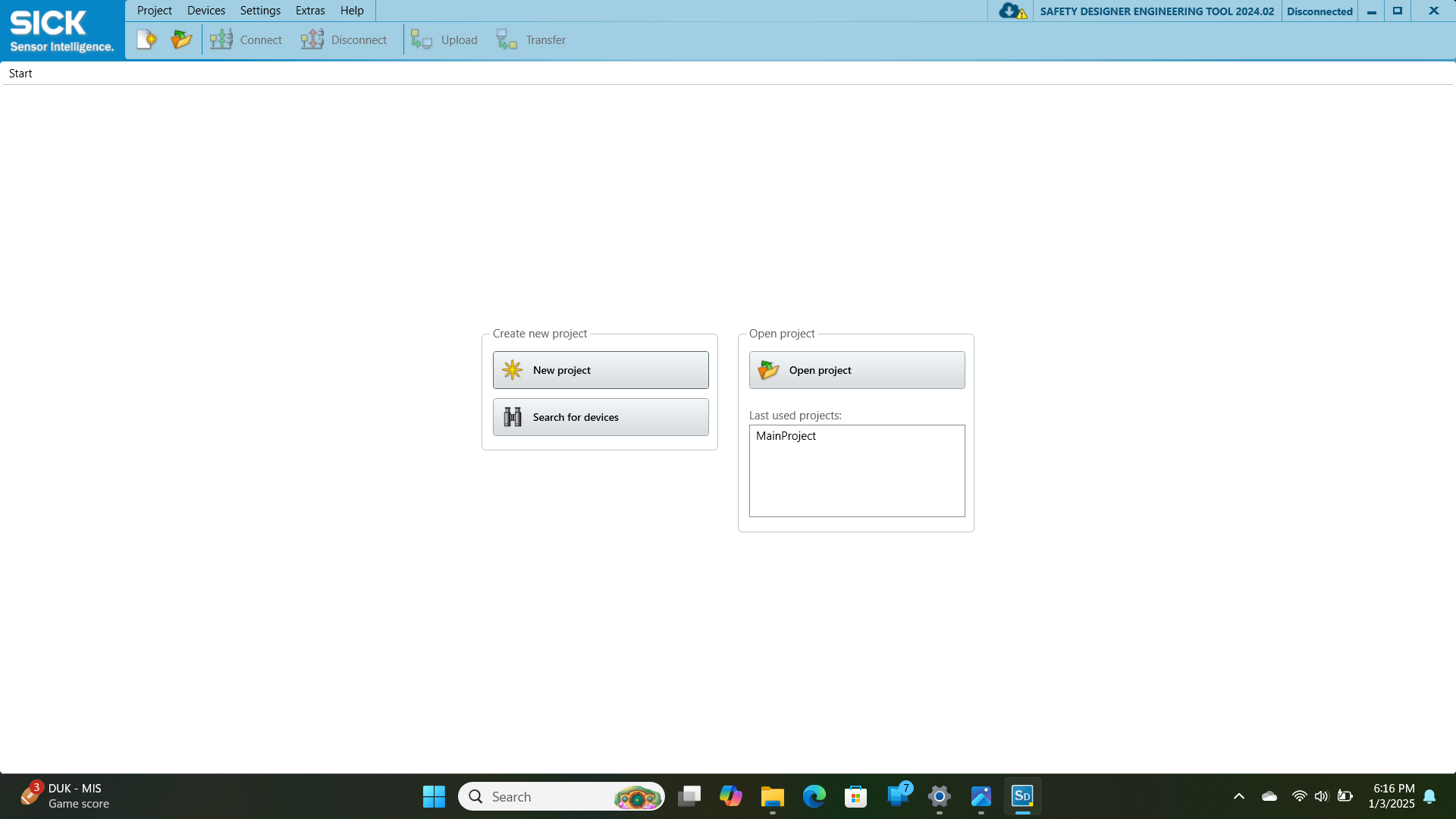

¶ Step 1: Launch Safety Designer

- Open the SICK Safety Designer software on your Windows computer

- You'll see the start screen with options to create a new project or open an existing one

- For first-time setup, choose "New project"

- For subsequent connections, you can select "Open project" to load a previously saved configuration

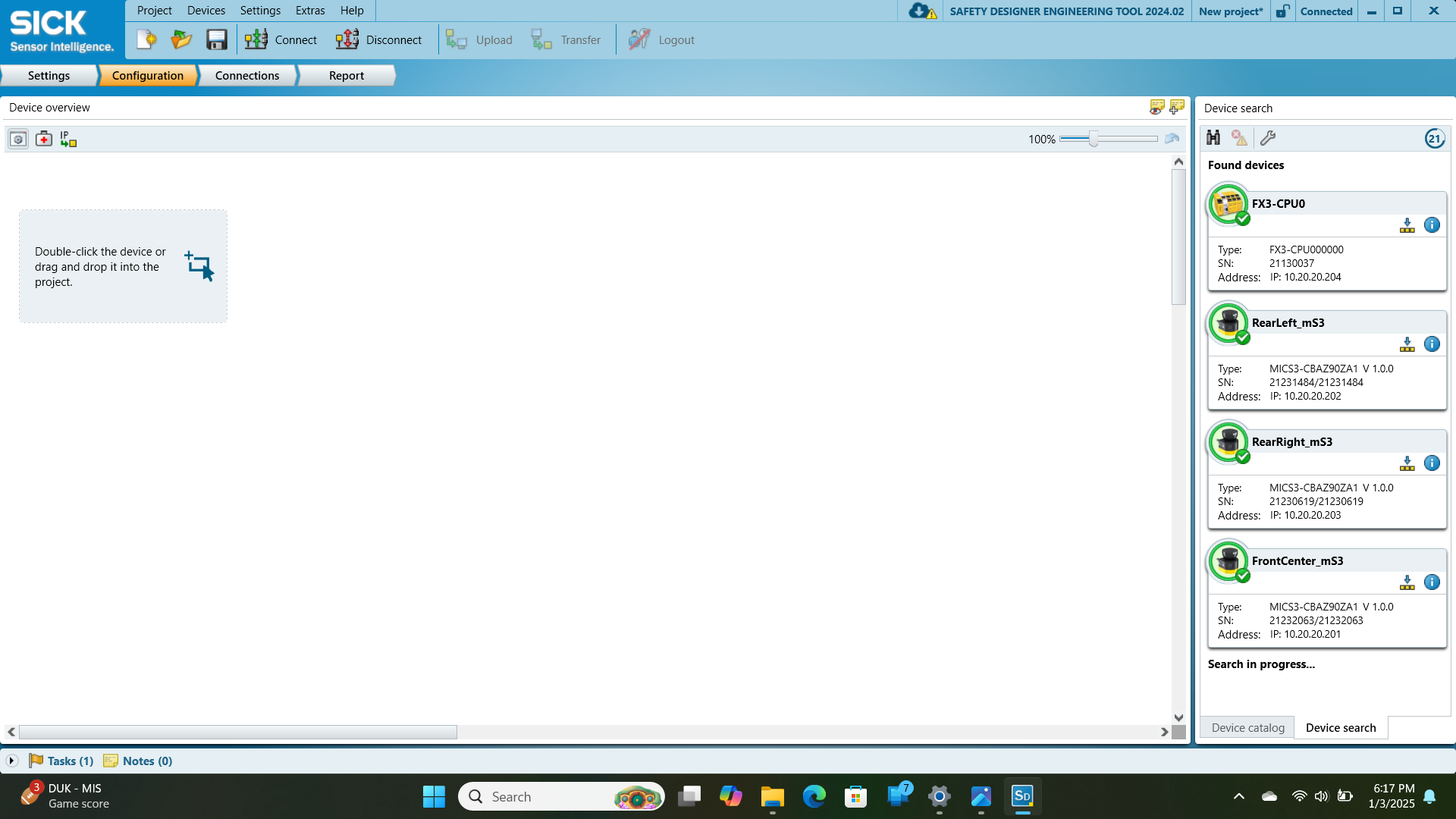

¶ Step 2: Search for Devices

- If starting a new project, click on "Search for devices" button

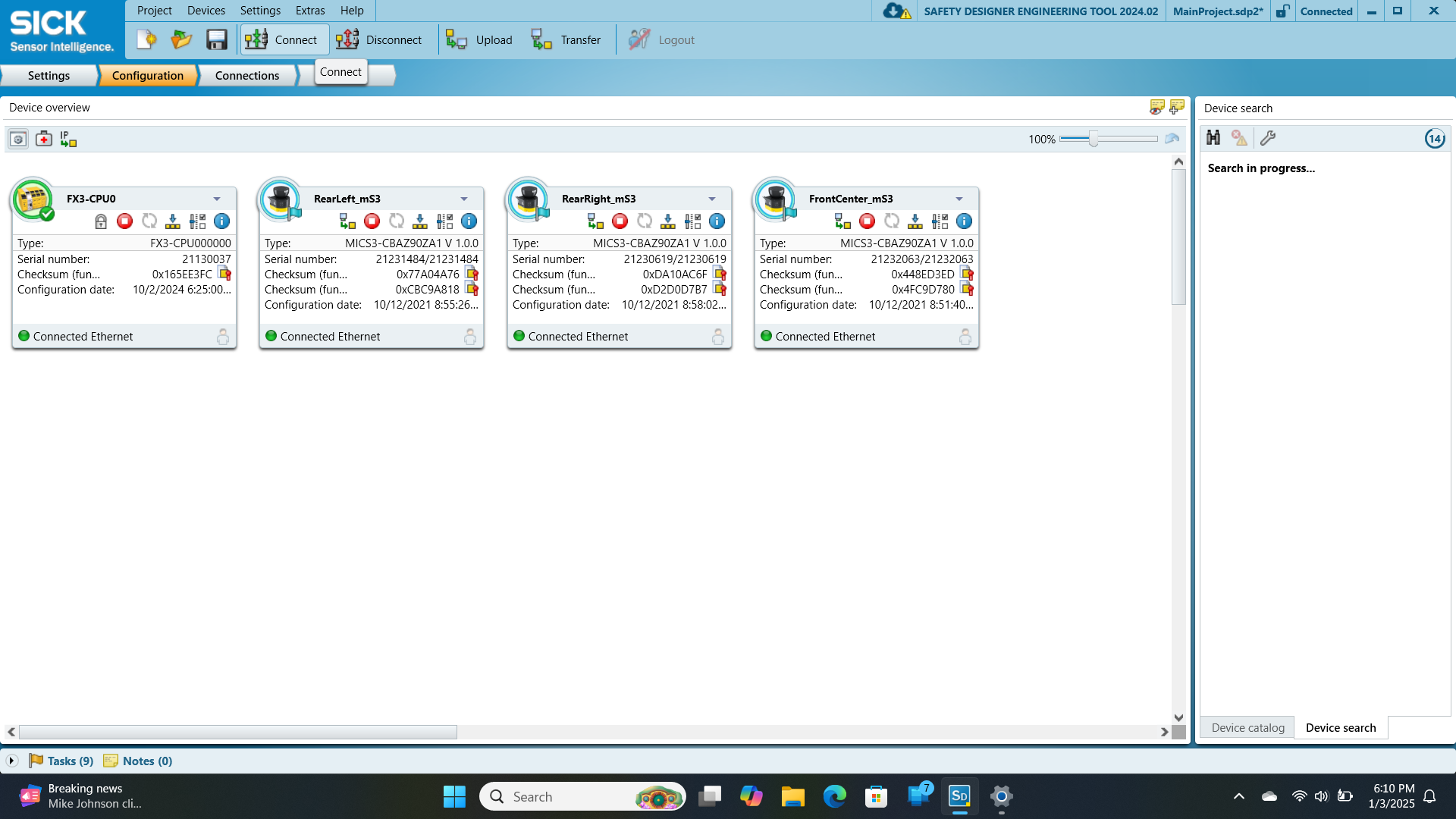

- The software will scan the network for compatible SICK devices as shown in the figure 5.2 below.

- Ensure your computer is on the same subnet (10.20.20.xxx)

¶ Step 3: Add Devices to Project

- Once devices are found, they will appear in the "Found devices" section

- In the right panel of

Device Searchfigure 5.2, you should see:- FX3-CPU0 (Main PLC controller) at IP: 10.20.20.204

- RearLeft_mS3 (Safety scanner) at IP: 10.20.20.202

- RearRight_mS3 (Safety scanner) at IP: 10.20.20.203

- FrontCenter_mS3 (Safety scanner) at IP: 10.20.20.201

- Double-click each device or drag and drop it into the project area

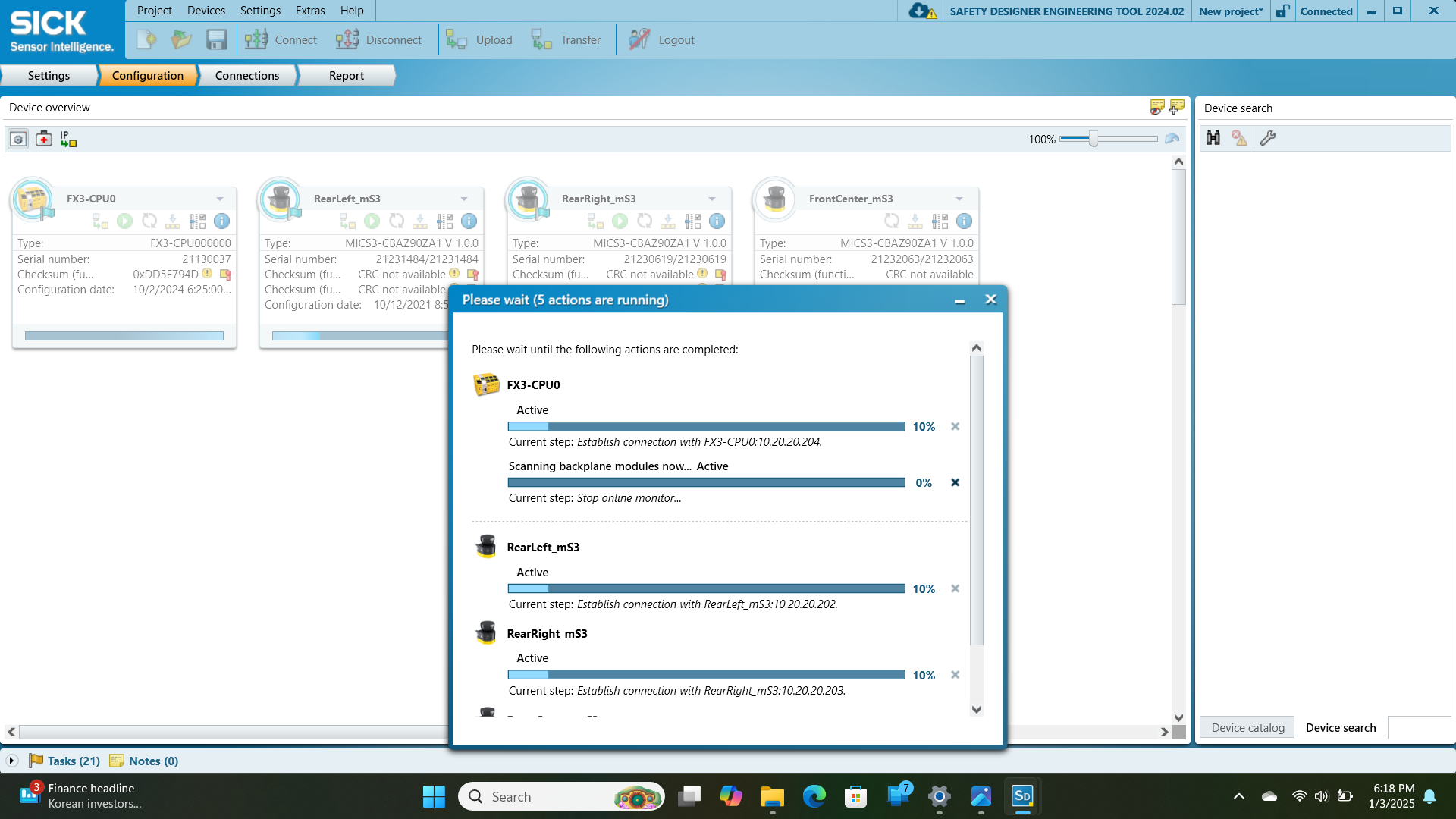

¶ Step 4: Wait for Connection

- The software will establish connections to all devices

- A progress dialog will appear showing "Please wait (x actions are running)" as shown in the figure 5.3 below.

- Connection steps for each device will be shown:

- "Establish connection with FX3-CPU0:10.20.20.204"

- "Establish connection with RearLeft_mS3:10.20.20.202"

- "Establish connection with RearRight_mS3:10.20.20.203"

- "Establish connection with FrontCenter_mS3:10.20.20.201"

¶ Step 5: Verify Connections

- Once all connections are established, green indicators will appear

- Each device will show "Connected Ethernet" status

- The main interface will display all connected devices with their details as shown in the below image:

- Device type

- Serial number

- IP address

- Safety network number

¶ Step 6: Save Project (Recommended)

- After successful connection, save your project

- Click "Project" → "Save As" and provide a descriptive name

- This allows you to quickly reconnect in the future by selecting "Open project" from the start screen

¶ 5.3 Understanding the System Configuration

The IronOX PLC safety system consists of two main components:

-

FX3-CPU0 (Main Controller):

- Contains all the control-related logic for the system

- Houses the emergency stop logic, restart conditions, and motor control safety

- This is where the programming changes have been made

-

Safety LiDARs (microScan3):

- Three units: FrontCenter_mS3, RearLeft_mS3, and RearRight_mS3

- Each LiDAR has configured safety fields for obstacle detection

- If you need to modify safety field configurations, select the specific LiDAR device

¶ 5.4 CPU Logic Modifications

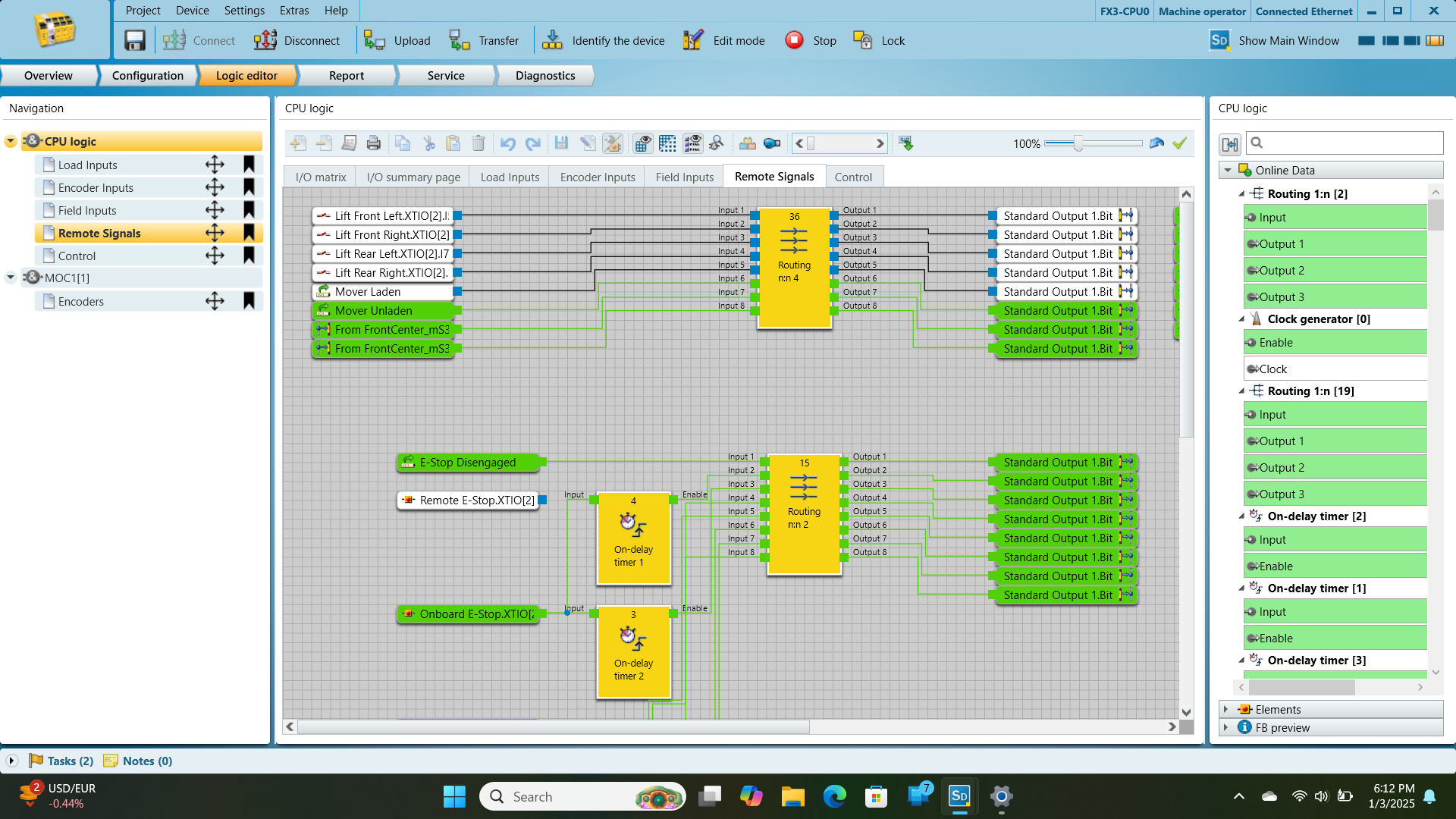

You can open the CPU logic by double clicking on the FX3-CPU0 icon.

The following changes have been made to the CPU logic to address radio emergency stop issues:

¶ 5.4.1 Emergency Stop System Changes

- Remote E-Stop Signal Bypass in Remote Signals Tab:

- In the "Remote Signals" tab, the connection between "Remote E-Stop.XTIO[2]" and the on-delay timer has been removed.

- This was necessary because the radio was consistently sending high signals to this pin, causing operational issues.

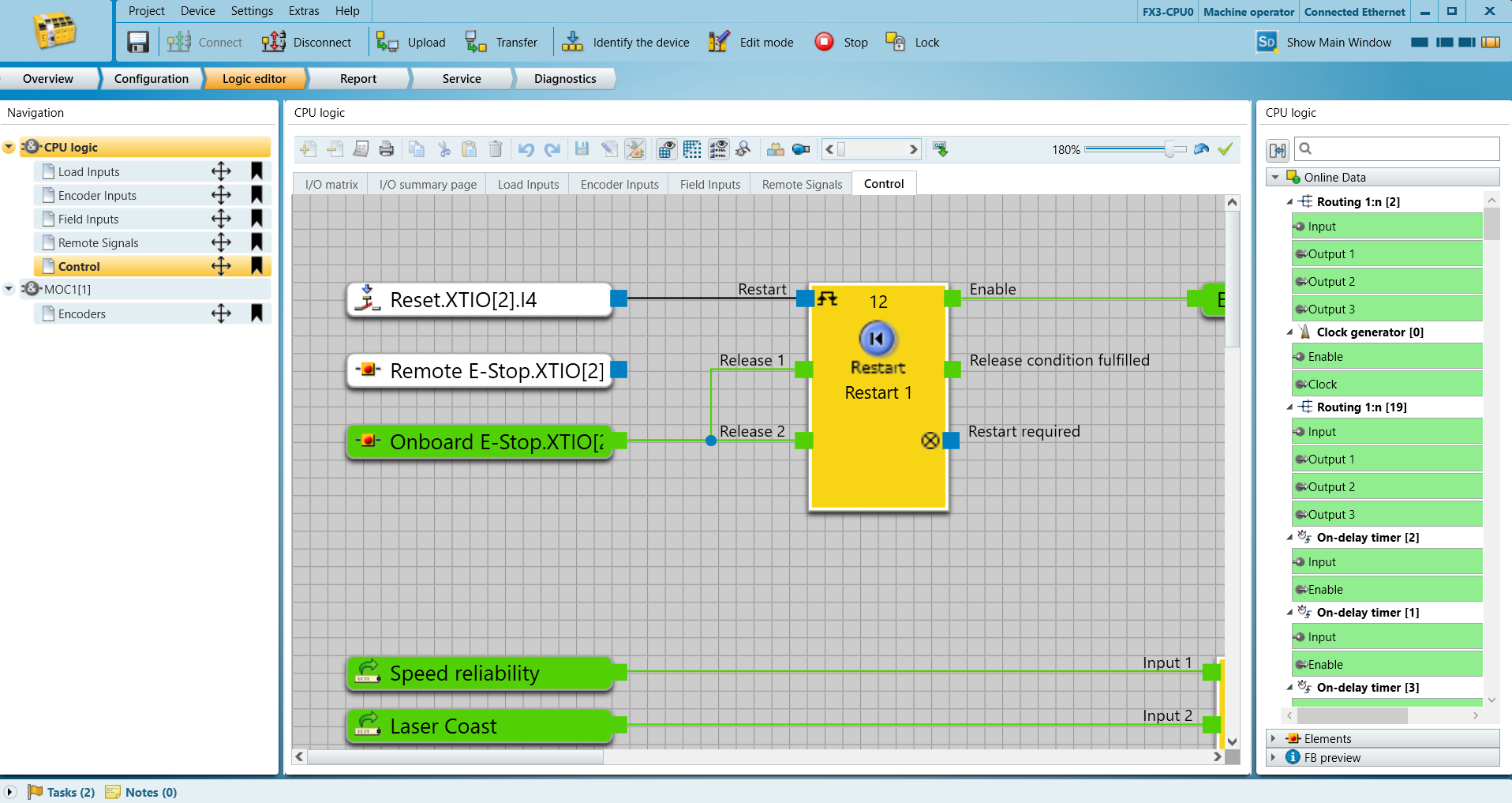

- Restart Logic Modification in Control Tab:

- In the "Control" tab, the connection between "Remote E-Stop.XTIO[2]" and the Restart block has been removed.

- The restart logic now only depends on the "Onboard E-Stop.XTIO[2]" signal.

- The system now only requires the physical onboard E-Stop to be released for restart.

¶ 5.4.2 Other Safety Systems

- The CPU logic still maintains other critical safety features:

- Reset button (Reset.XTIO[2].I4) for manual recovery after emergency stop

- Speed reliability monitoring

- Laser Coast protection

- Physical E-Stop functionality remains fully operational

¶ 5.5 Uploading Configuration Changes

After making modifications to the safety logic, follow these steps to transfer the changes to the PLC:

-

Verify Logic Integrity:

- Check all connections to ensure they are correctly made

- Verify that removal of the Remote E-Stop connections doesn't affect other safety systems

-

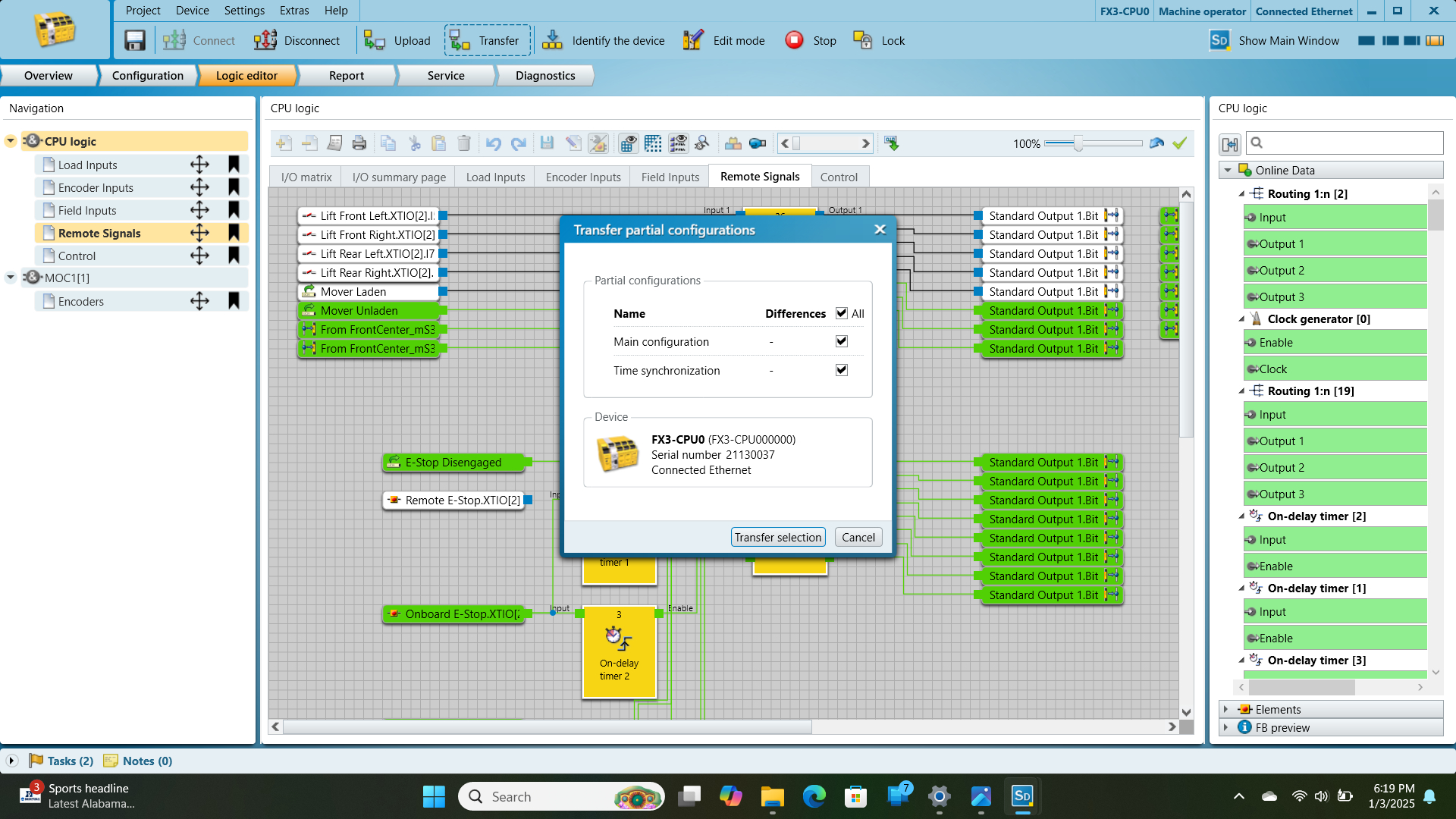

Initiate Transfer:

- Click the "Transfer" button in the toolbar

- Note: "Upload" means transferring data FROM the PLC TO the computer, while "Transfer" means sending data FROM the computer TO the PLC (PLC is the point of reference)

- A dialog showing partial configurations will appear

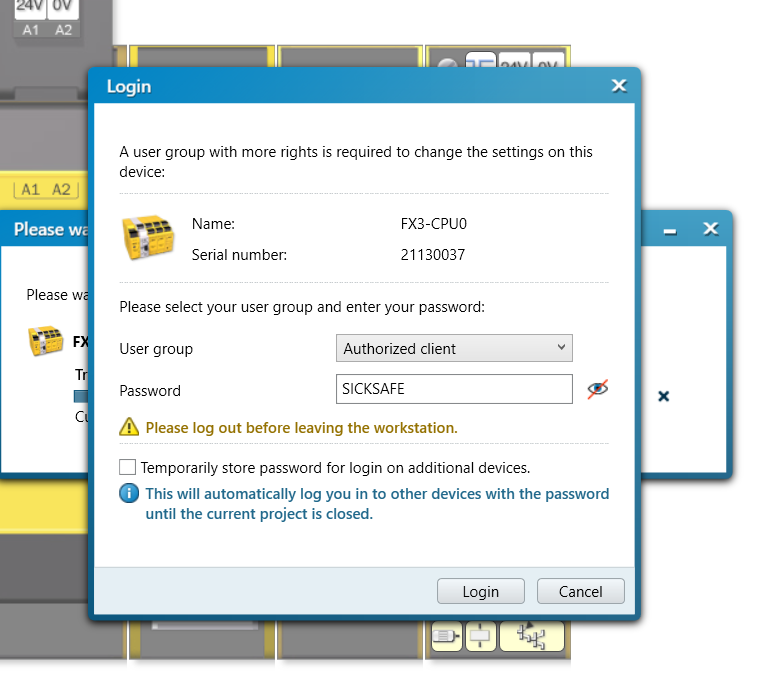

- Authentication:

- You will be prompted to log in with proper credentials

- Select

Authorized clientfrom the dropdown menu - Enter the password:

SICKSAFE - Click

Loginto proceed

-

Complete Transfer:

- Click "Transfer selection" to send the configuration to the PLC

- A progress bar will show the transfer status

- Wait for the transfer to complete successfully

- The system will indicate when the transfer is finished

-

Verification:

- After transfer, verify that the system operates as expected

- Test the physical E-Stop functionality

- Confirm that the system can properly restart after an E-Stop event

-

Future Resolution:

¶ 5.6 Project Backup and Change Documentation

It's critical to create backups of your safety configuration before making any changes. This provides a safe fallback option in case issues arise with new configurations.

¶ Creating a Backup

-

Initial Project Saving:

- After first connecting to the PLC but before making any changes, save the initial project

- Click "Project" → "Save As" and give it a descriptive name like "IronOX_PLC_Original_Configuration"

- Include the date in the filename for version tracking

- This creates a complete backup of the original system state

-

Version Control:

- When making significant changes, save under a new filename

- Use a naming convention like "IronOX_PLC_RadioEStop_Bypass_20250123"

- This maintains a history of changes and configurations

-

Export Configuration:

- For additional backup, use the "Export" function

- Click "Project" → "Export" and save the file to a secure location

- Consider storing backups on a separate device or cloud storage

-

Default Backup:

- A default backup of the original PLC configuration can be downloaded from TODOLink

- This factory default can be used to restore the system to its original state if needed

¶ 6. Connecting to the ELMO Motor Driver(TODO)

¶ Guide

¶ 7. Software Architecture Overview(TODO)

- A block diagram illustrating the layered architecture of the system will be included here.

- Code Filesystem Overview: